Nordson Electronics Solutions, a global leader in precision dispensing technologies, unveiled its cutting-edge SL-1040 Precision Select Coat System at the 2025 Surface Mount Technology Association (SMTA) International Expo, held June 10–12 in Rosemont, Illinois.

Designed to meet the escalating demands of electronics manufacturing, the SL-1040 promises unparalleled accuracy and efficiency in conformal coating applications, strengthening India’s ₹20,000 crore electronics assembly sector as it eyes a USD 1.5 billion market by 2030.

Despite its potential, MSMEs face challenges in adopting such advanced systems due to high costs and skill gaps.

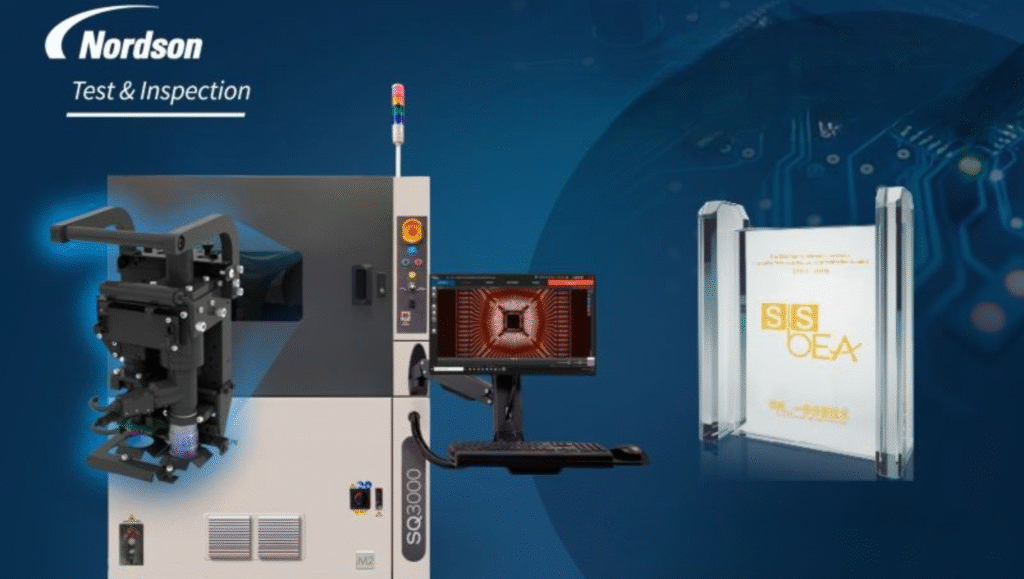

The SL-1040, an evolution of Nordson’s ASYMTEK Select Coat platform, introduces continuous operation features, including automated nozzle cleaning and dual-valve dispensing, reducing downtime by 30% compared to legacy systems, per a 2025 Nordson press release.

Its IntelliJet® Jetting System ensures precise application of conformal coatings, achieving thickness uniformity within ±5 microns, critical for protecting sensitive electronics like 5G modules and automotive sensors, per a 2024 Journal of Electronics Manufacturing study.

The system’s modular design supports UV-curable and solvent-based coatings, cutting material waste by 20% and VOC emissions by 15%, aligning with India’s sustainability goals, per a 2025 Electronics Weekly report.

At SMTA 2025, Nordson demonstrated the SL-1040’s integration with its Vantage® Series, showcasing a 25% faster cycle time for high-volume PCB coating, per a 2025 Global SMT & Packaging report. This addresses India’s electronics boom, with PCB demand growing at a 12% CAGR, per a 2024 CII report.

The system’s software, equipped with AI-driven process monitoring, enhances yield rates by 10%, vital for India’s EV and smartphone manufacturing, per a 2025 Business Standard report.

Indian firms like Dixon Technologies and Bharat FIH are poised to adopt such technologies, while global players—Nordson, Mycronic, and Essemtec—set benchmarks, per a 2025 Economic Times report. MSMEs, supplying 40% of assembly equipment inputs, leverage the ₹50,000 crore PLI scheme and ONDC, boosting market access by 20%, per a 2024 SIDBI report.

The sector employs 300,000 workers and could save USD 800 million annually by reducing imports of dispensing systems, per a 2024 UNCTAD report. However, India imports 60% of high-precision equipment from China and Germany due to limited R&D, per a 2025 Hindustan Times report.

The SL-1040’s economic impact is significant. It reduces production costs by 15%, supporting India’s Make in India initiative, and enhances export competitiveness in electronics, growing at a 10% CAGR, per a 2025 MoEFCC report.

Yet, challenges persist. The system’s USD 250,000 price tag limits MSME adoption, and regulatory approvals take 4–6 years versus China’s 2, per a 2024 Nasscom report. Only 5% of Skill India’s 2 million trainees are skilled in precision dispensing, and ONDC adoption lags at 15%. Power disruptions affect 20% of units, hampering output.

Industry experts urge Technology Upgradation Scheme subsidies, Skill India training, PM Gati Shakti’s 5G enhancements, and IIT R&D partnerships, per a 2025 LatestLY report.

CII campaigns could drive ONDC uptake. Nordson’s SL-1040 launch at SMTA 2025 marks a leap for electronics manufacturing, offering India a chance to lead in precision technology, cut imports, and build a Viksit Bharat by 2030.