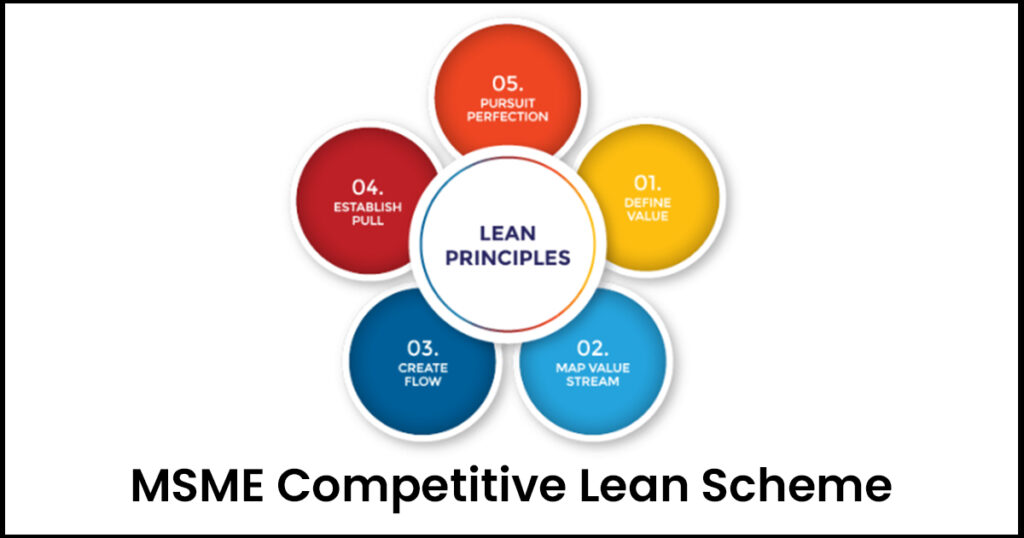

The Government of India, through the Ministry of Micro, Small and Medium Enterprises (MSME), continues to push forward its Lean Manufacturing Competitiveness Scheme (LMCS), more popularly known as the Lean Scheme, with renewed focus and relevance in 2025. This initiative is tailored to make Indian MSMEs more efficient, quality-driven, and globally competitive by encouraging the adoption of proven Lean manufacturing techniques.

The Lean Scheme aims to instill best practices like 5S (Sort, Set in Order, Shine, Standardize, Sustain), Kaizen (continuous improvement), Kanban (inventory control), Just-in-Time (JIT), Poka-Yoke (error-proofing), and Value Stream Mapping. These tools are widely used by industries across the world to cut waste, improve quality, enhance process efficiency, and increase customer satisfaction.

One of the primary features of the scheme is the financial assistance provided by the government. Up to 90% of the implementation cost is covered under this scheme, thereby making it feasible for even the smallest of enterprises to adopt these advanced methods. MSMEs that enroll in the scheme typically show improvements in productivity, cost reduction, faster delivery, better inventory management, and more motivated staff — making their operations leaner and more profitable.

The Lean Scheme follows a cluster-based approach. A group of 10 to 12 MSMEs with similar business activities or located in close geographical proximity form a Lean Manufacturing Cluster (LMC). The cluster applies through the official MSME portal or the nearest MSME Development Institute. Once approved, a qualified Lean Manufacturing Consultant is assigned to the cluster. The process begins with a diagnostic study to identify gaps and areas for improvement. This is followed by the implementation of lean practices in a phased manner, supported by training sessions and on-site demonstrations.

The policy places strong emphasis on knowledge-sharing and peer learning within the cluster, creating a culture of collective growth. The focus is not only on improving internal systems but also on helping MSMEs integrate with global supply chains and meet international standards. As part of India’s larger goals under Atmanirbhar Bharat and Make in India, the Lean Scheme also facilitates the digital transformation of MSMEs and lays the groundwork for Industry 4.0 readiness.

Industries such as textiles, auto components, chemicals, packaging, coatings, electronics, and engineering have seen particular benefit from the scheme. For example, in the paints and coatings sector, lean adoption has helped in better batch processing and reduction in rework. In the FMCG and chemical sectors, lean tools have contributed to faster line changeovers and reduced raw material wastage — improving bottom-line efficiency and sustainability.