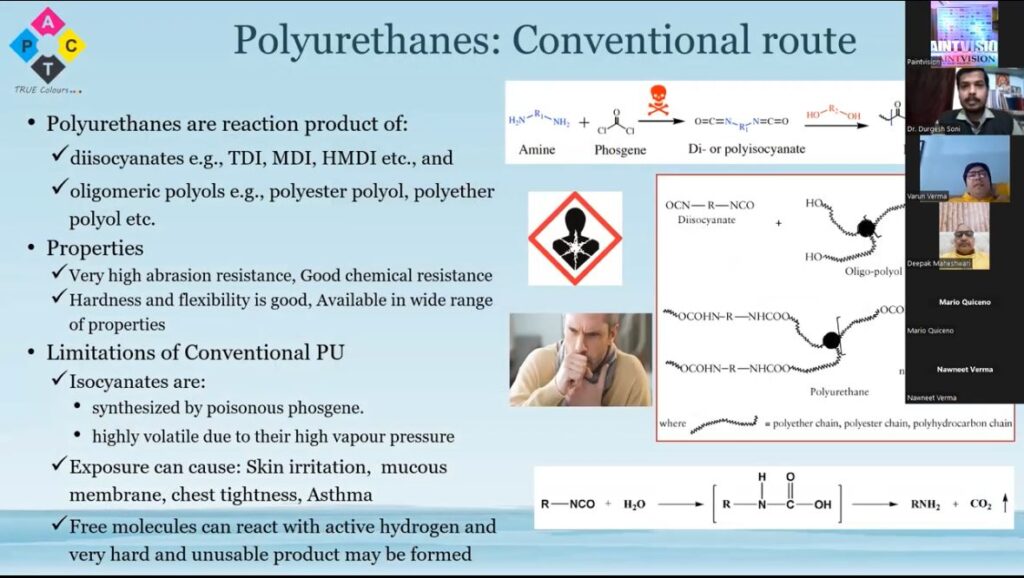

The world of paints and coatings extensively depends on polyurethanes, a category of materials that are highly tough, versatile, and resilient. There is nevertheless a cost to these merits: the use of isocyanates in their manufacture. Isocyanates are notorious respiratory irritants with grave health effects, which raises environmental concerns.

Non-isocyanate polyurethanes (NIPUs) are an innovative class of materials emerging as sustainable alternatives in paint technology. This paper discusses the potential of NIPUs by examining their chemical composition, production techniques, and impact on the paint industry’s environmental footprint.

Conventional polyurethanes result from the reaction between isocyanates and polyols. However, isocyanates are known to be particularly reactive chemicals, with well-known linkages to respiratory problems such as asthma and irritation. The challenge faced by the paint industry, which is heavily dependent on polyurethane, is balancing performance with employee and environmental safety.

Regulations around isocyanate use are becoming increasingly stringent; therefore, paint manufacturers have been searching for safer options. That’s where NIPUs come into play, providing a promising answer without having to use any kind of isocyanate.

By using a different path, NIPUS emulates the functions of regular polyurethanes. The most prevalent method for preparing NIPUs is through the reaction of cyclic carbonates and amines. Cyclic carbonates refer to cyclic esters of carbonic acid, while amines denote organic molecules with a nitrogen atom. This process doesn’t produce any harmful byproducts, unlike the isocyanate pathway, thus making it safer and more environmentally friendly.

This procedure was discussed more extensively by Dr. Durgesh Soni in the webinar. His research focuses on cyclic carbonate and amine chemistry for NIPU synthesis. There are several advantages to this:

- Safety in production: The absence of isocyanates from NIPU production significantly reduces worker exposure to toxic substances, thereby creating a safe work environment.

- Environmentally-friendly products: Carbon dioxide (CO2) is incorporated into the synthesis of NIPUs. It acts as one of the greenhouse gases that can be captured from industrial activities and then used as raw material for producing NIPUs, hence contributing to greener manufacturing practices.

- Curing at room temperature: While some conventional polyurethanes cure at room temperature, leading to energy-intensive processes, others don’t. Therefore, less paint manufacturing requires less energy consumption, which will ultimately result in low energy use per unit weight during paint manufacture.

As much as NIPUs promise sustainability, their performance is still in question for traditional polyurethanes. In his presentation, Dr Soni takes into account that NIPUs may differ slightly from their counterparts in mechanical properties like hardness and scratch resistance.

That doesn’t mean it’s impossible, though. Different approaches are being used in synthesising these materials to enhance their physical properties for specific purposes. Even more, they can be doped with other bio-based materials to achieve specific functional attributes.

The development of NIPUs has just started, but there could be a revolutionary change within the paint production industry due to this. Further research is needed to bridge the performance gap and optimise different types of paints using NIPU formulations. The major areas of concern will include:

- The mechanical properties of NIPUs need to be improved, and this can be achieved if researchers understand how the structure affects properties and find strategies that enhance their mechanical performance without undermining their environmental advantages.

- Compatibility with Existing Systems: For successful incorporation into current production processes, it is important to investigate the compatibility between NIPUs and existing paint formulations as well as pigments used in paints.

- Cost-Effectiveness: This calls for research into cost-effective production methods for NIPUs to develop them as commercially viable polyurethanes capable of competing with traditional ones.

Researchers, paint makers, and suppliers of raw materials must collaborate for the faster development and acceptance of NIPU technology. This information sharing helps in creating performance-oriented and sustainable paints that are environment-friendly as well as safe for workers.

NIPUs are a major milestone towards a more sustainable paint industry since they do not contain harmful isocyanates and use CO2 to make them different from conventional polyurethanes. Nevertheless, some performance considerations remain unresolved, but there is great hope that such challenges could be tackled through further research in this area. Therefore, ongoing innovation and collaboration can change the face of the paint market and integrate sustainability into its future aspects.